- Control system: Schneider PLC Controller+ 7inch schneider color touch screen. All the machine are pneumatic, to make sure machine work stable.

- Schneider servo motor

- Japan Omron relay, keep machine work with less than ±1℃ accuracy.

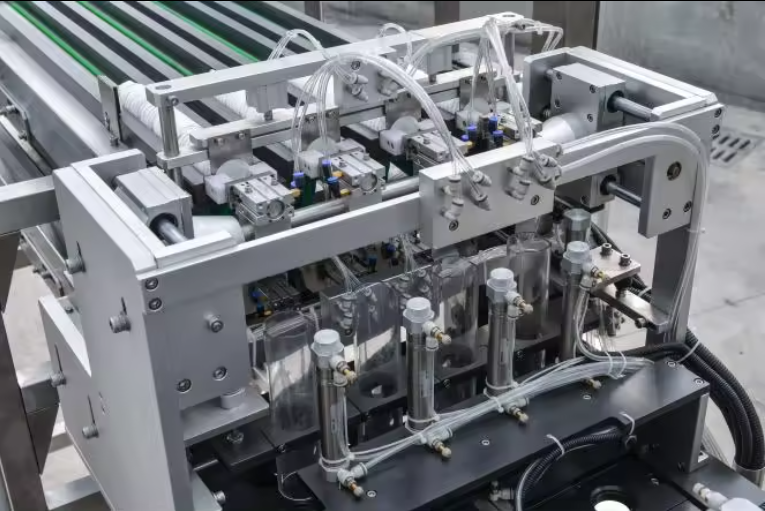

- Cylinder: Air TAC cylinder.

- Molds : Used acid-proof molds.

- All machine Frame outsourcing are 304 stainless steel with 2mm thickness, and the filling system and all touch the products are all made of 304 stainless steel.

- Filling system: Screw feed and press tightly type. With mix tool (Auger) in the hopper, which will stir the hopper contents in order to get the coffee to fall from the hopper for filling automatically, avoid contents stuck when filling, need operator to stir always, which is labor-waste.

- Touch Screen control

Working Process:

- Empty capsule loading

- nitrogen flushing

- coffee filling & pressing

- nitrogen flushing into hopper

- nitrogen flushing

- lid loading

- Sealing

- finished capsules dropping down

- mold cleaning.