Features

- Capable of producing Nespresso, Lavazza Blue, Dolce Gusto, and other capsule formats through mold changeover.

- Triple nitrogen flushing process ensures maximum freshness and extended shelf life of the coffee capsules.

- Uses globally recognized brands for electrical and pneumatic components (e.g., Schneider, Siemens, Omron).

- Automatic counting of total capsules and preparation for downstream packaging.

- The automatic overturning device quickly discharges the current batch and prepares the next one for filling and sealing.

- Equipped with 4 cavities in line delivering high output with exceptional consistency superior to general filling machines.

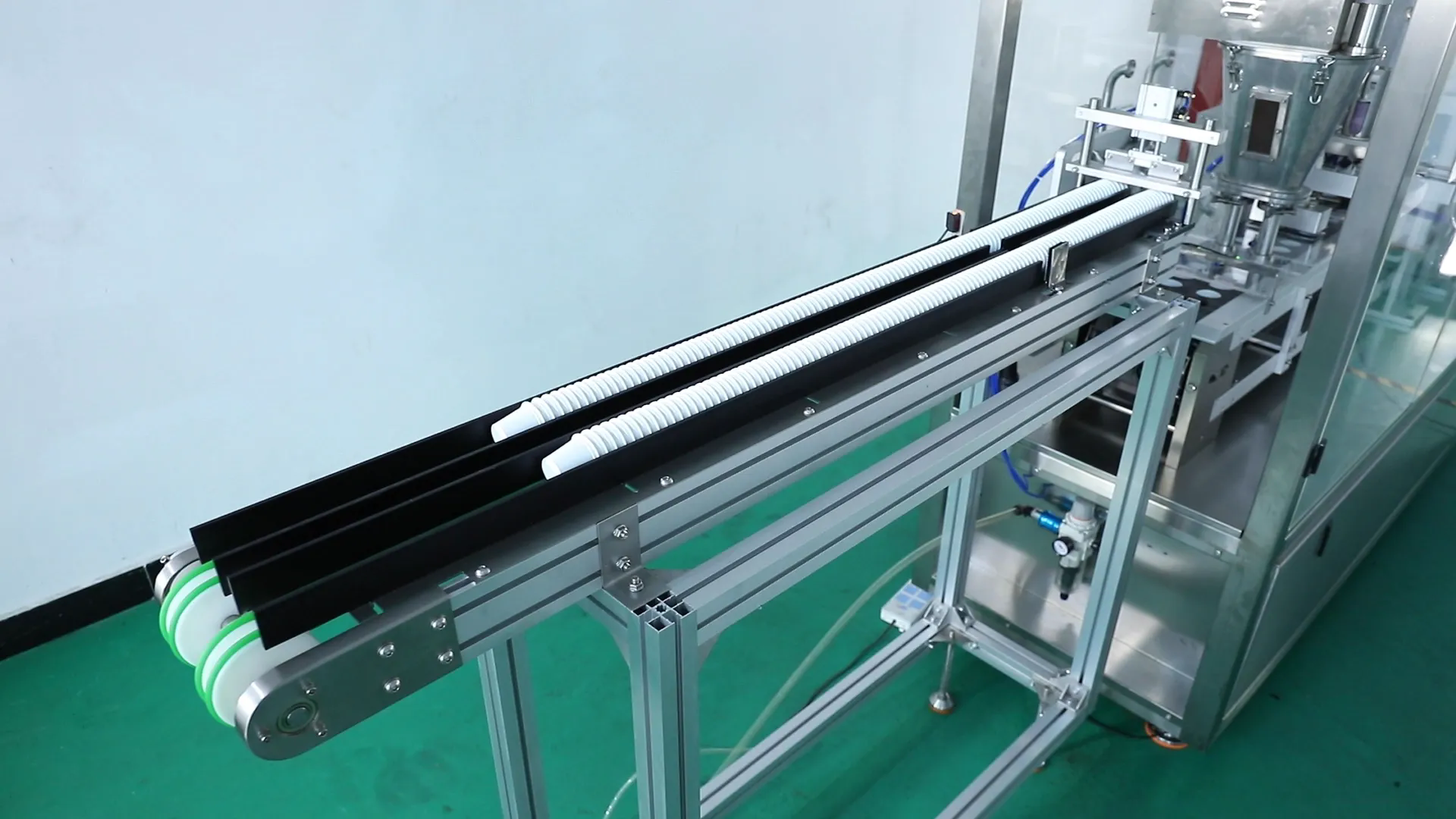

- Easily integrates with a cartoning machine, enabling a smooth upgrade to your manufacturing line for enhanced efficiency.

- High-resolution servo system ensures pinpoint accuracy, while the in-line weighing system offers real-time weight monitoring for consistent filling and quality control.

- Capsule sorter and lifting and conveying system greatly save labor costs; The high-quality pneumatic components make the air circuit of the machine run stably

- The peristaltic pump drop filling device is ready for adding liquid flavors in the capsule in the future

Specifications

| Capacidad | 200cpm |

| Cabezal de llenado | 4 |

| Modo de medida | llenado de barrena |

| rango de llenado | 5-15g(adjustable) |

| Power supply | 1.2kw |

| Material de sellado | Tapa de aluminio troquelada |

| Equipamiento opcional | Compresor de aire |

| Air Consumption | 0.3m³/ min |

| Nitrogen Consumption | 0.25m³/H |

| Noise | <70DB |

| Air pressure needed | 0.6–0.8Mpa |

| Dimensión global | 3400 (L) X 1800 (w) X 2600 mm(H) |

| Peso | 2000KG |

| Forma de embalaje | Caja de madera |

Advantages

01

Precise Feeding and Filling

Adopting a world-class PLC control system and the streamlined design of the filling screw allows for a filling accuracy of 0.1g.

02

Enclosed Exterior Design

Fully enclosed design, 304 stainless steel and UV sterilization ensures maximum hygiene and prevents contamination during production

03

Nitrogen Filling

High-precision nitrogen filling device keeps oxygen content within the capsule under 2%, ensuring that the contents stay fresh upon sealing.

04

Intuitive Double Sealing Techniques

Two rounds of heat sealing, eliminate the risk of defective products entering the market, even if the first heat seal fails

05

Consistent Air Flow

High-quality pneumatic components keep the air pressure running even and stable, improving the machine’s production capacity and service life by reducing failure rates.

06

Top-tier Production Speed

Equipped with 4 in-line cavities, this machine delivers faster filling and sealing speeds than most coffee packaging machines on the market.

Diverse Cup Styles the SK-4 Can Process

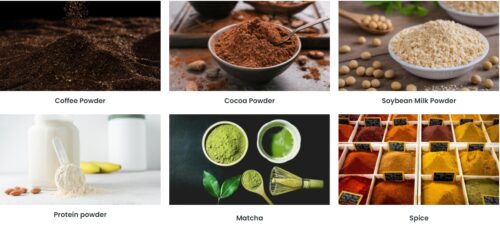

Related Powder Materials

Not stopping at processing coffee products, the SK-4 can also be used for different powdered products with equally consistent results.

Why Choose SANEU?

With over a decade of pioneering experience in the coffee packaging industry, SANEU empowers numerous coffee roasters and factories worldwide, enabling them to achieve fully automated production of K-Cup, Nespresso, and Dolce Gusto compatible coffee pods. Our commitment to precision engineering and robust performance ensures seamless integration into your existing operations, delivering consistent quality and maximizing throughput. Choose SANEU to transform your coffee packaging process into a high-end, efficient, and reliable operation.

Machines Videos