Features

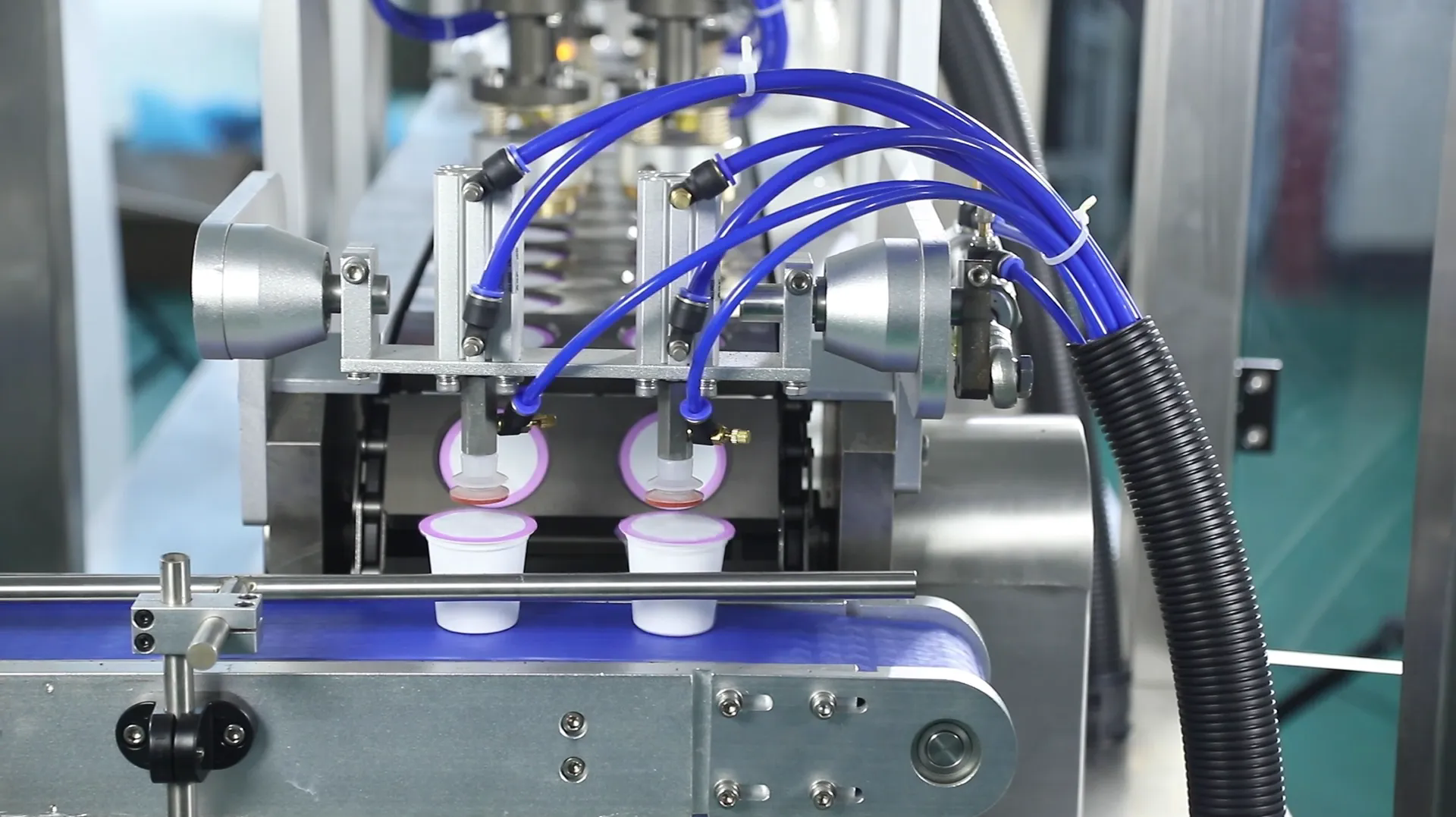

- Auger/screw filling system ensures consistent and precise filling.

- All parts in contact with food are made of 304 stainless steel, ensuring hygiene and durability.

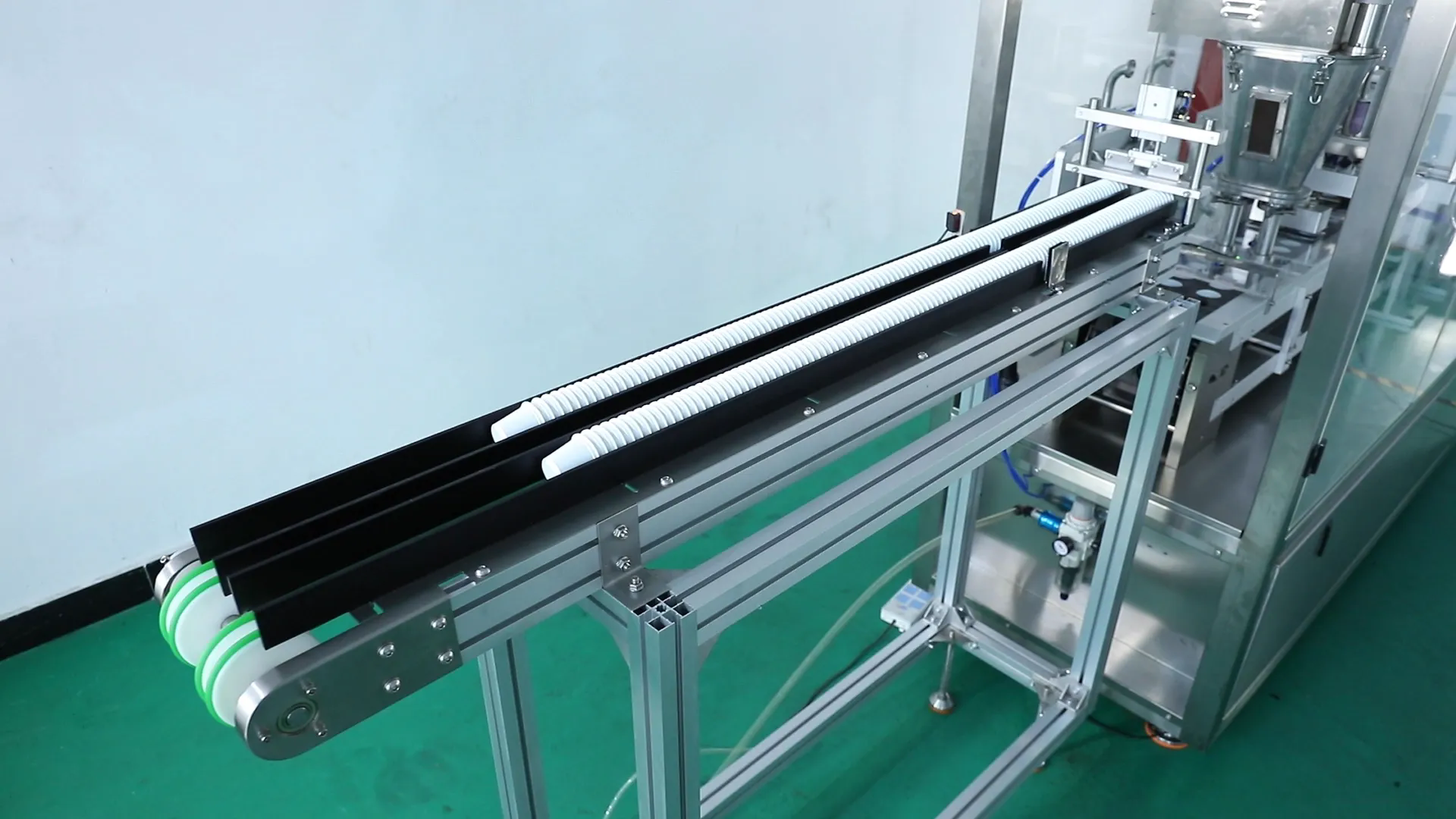

- Capsule sorter and lifting/conveying system reduce labor costs.

- Automatic counting of total capsules and preparation for downstream packaging.

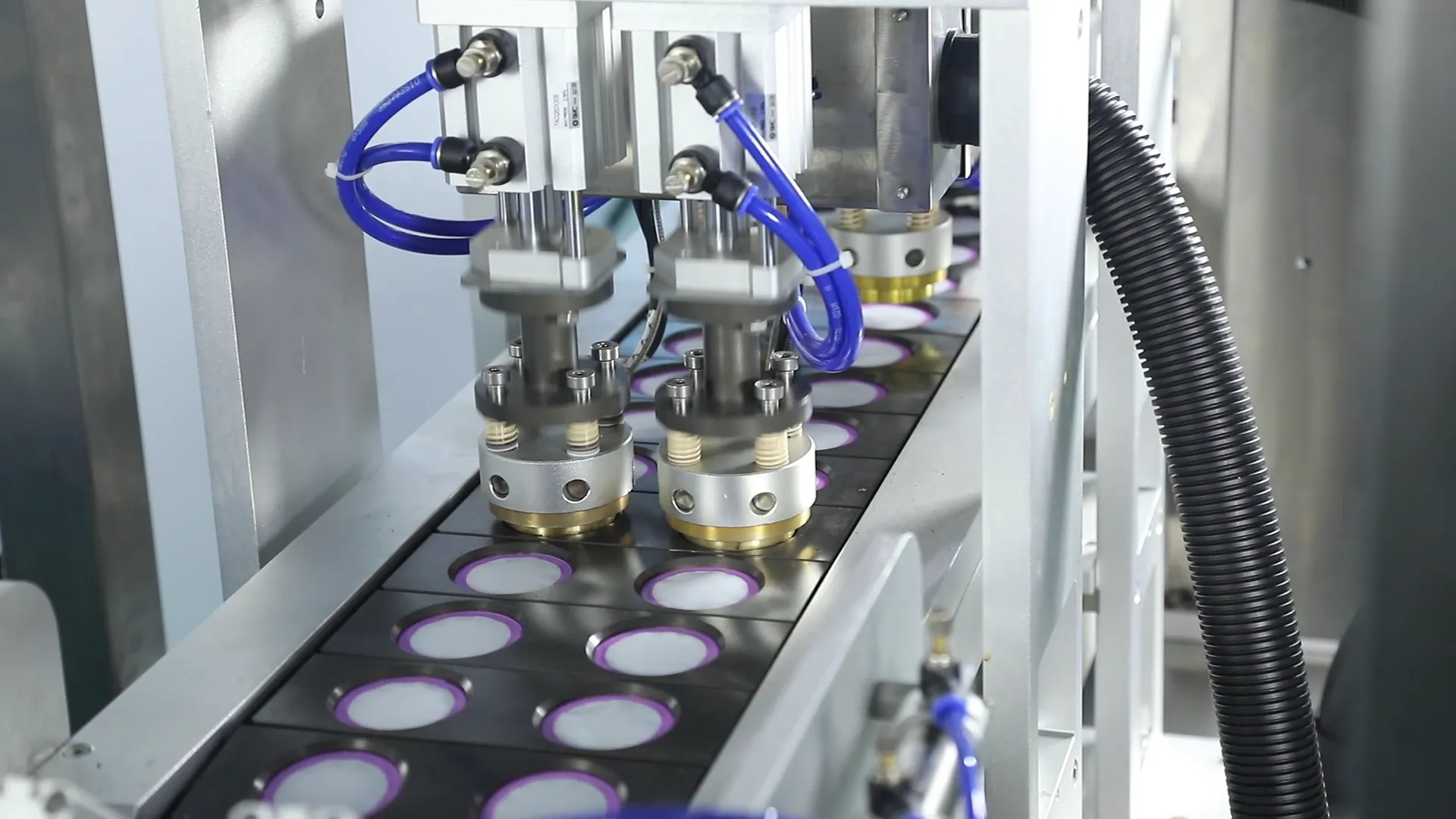

- High Resolution servo systeme and detective sensor enables pinpoint operating accuracy.

- In-line weighing system provides real-time weight monitoring, ensuring consistent filling and quality control.

- Sensor detection ensures capsules are only filled when properly placed, reducing waste and boosting efficiency.

- Top-grade chain wheels, gearboxes, bearings, and dividing boxes for fast and accurate movement

- Seamlessly integrate with a cartoning machine and allow for upgrading manufacturing line.

- Ready for future upgrades, including peristaltic pump drop filling for liquid flavors.

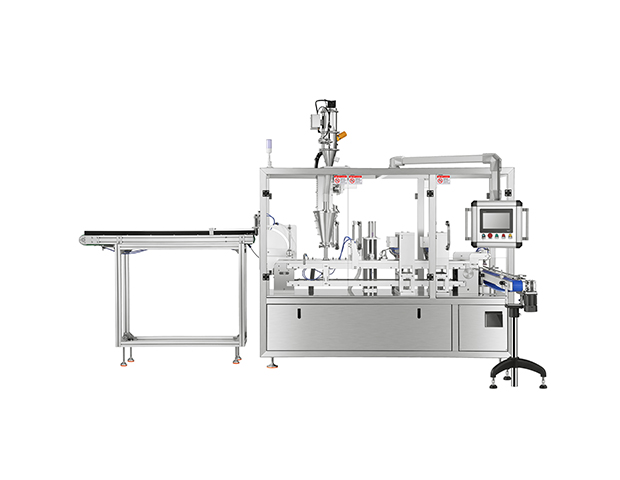

Specifications

| Kapasitas | 200cpm |

| Mengisi kepala | 2 |

| Ukur cara | Auger filling driven by Schneider servo motor |

| Kisaran pengisian | 5-15g(adjustable) |

| Power supply | 200V 50/60HZ 5KW |

| Bahan penyegel | Tutup foil yang sudah dipotong |

| Peralatan opsional | 15KW air compressor + nitrogen generator |

| Air Consumption | 0.5m³/ min |

| Nitrogen Consumption | 0.9m³/H |

| Noise | <75DB |

| Air pressure needed | 0.6–0.8Mpa |

| Dimensi keseluruhan | 3400 (L) X 1100 (w) X 2600 mm(H) |

| Berat | 1500KG |

| Cara Pengepakan | Kotak kayu |

Advantages

01

Outstanding Efficiency

Robust design and optimized functionality deliver exceptional throughput while scaling up production seamlessly.

02

Precise Feeding and Filling

Adopting a world-class PLC control system and the streamlined design of the filling screw allows for a filling accuracy of ± 0.2g.

03

Nitrogen Filling

High-precision nitrogen filling device keeps oxygen content within the capsule under 2%, ensuring that the contents stay fresh upon sealing.

04

Intuitive Filling and Sealing

Pure copper heating heads, superior screw auger, and branded serve motor incorporating seamlessly ensure consistent filling and sealing results.

05

Ready for Production Line

Horizontal structure allows coffee manufacturers to integrate a cartonning machine, paving the way for customers to build large-scale production lines in the future.

06

Smooth Production

The machine utilizes a combination of top-tier chain wheels, gearboxes, bearings, and dividing boxes to keep the production process fast, stable, and accurate.

Diverse Cup Styles the SK-2 Can Process

Related Powder Materials

Not stopping at processing coffee products, the SK-2 can also be used for different powdered products with equally consistent results.

Why Choose This Machine?

The SK-2 Filling and Sealing Machine offers precision, speed, and versatility for your capsule production needs. It features fully automated operation, ensuring high efficiency with minimal human intervention. Designed to handle multiple capsule sizes, whether filling liquid, granules, or powder. The horizontal design is ready for integration into the production line with a cartooning machine, which is beneficial for large-scale production upgrades.

Machines Videos