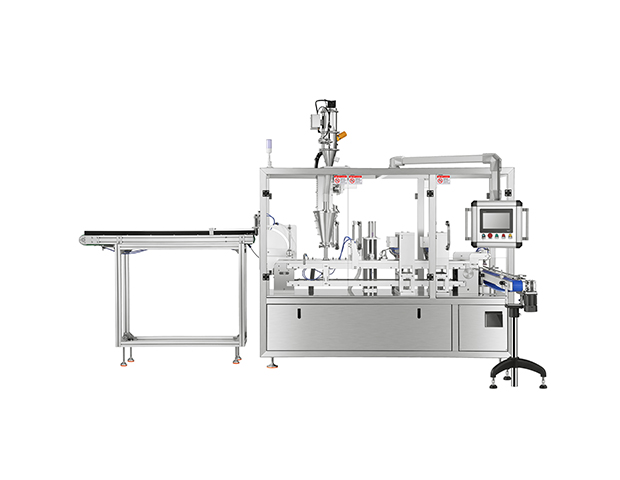

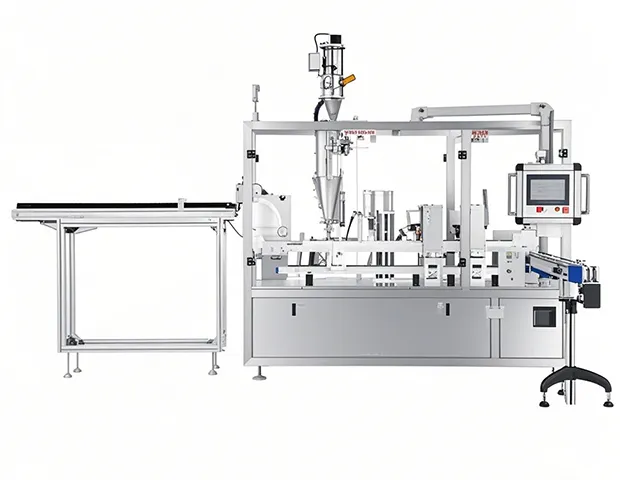

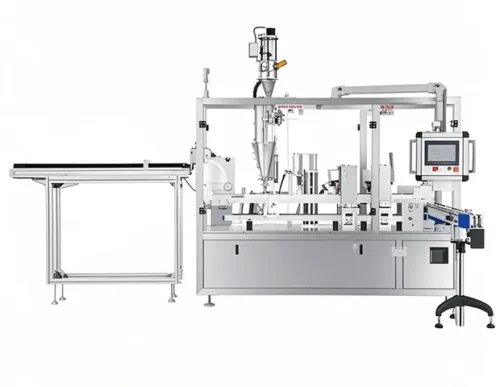

Based on SIEMENS/ORMON PLC and SIEMENS/ORMON HMI control, automatic pneumatic machine.

l One key operation, real-time monitoring.

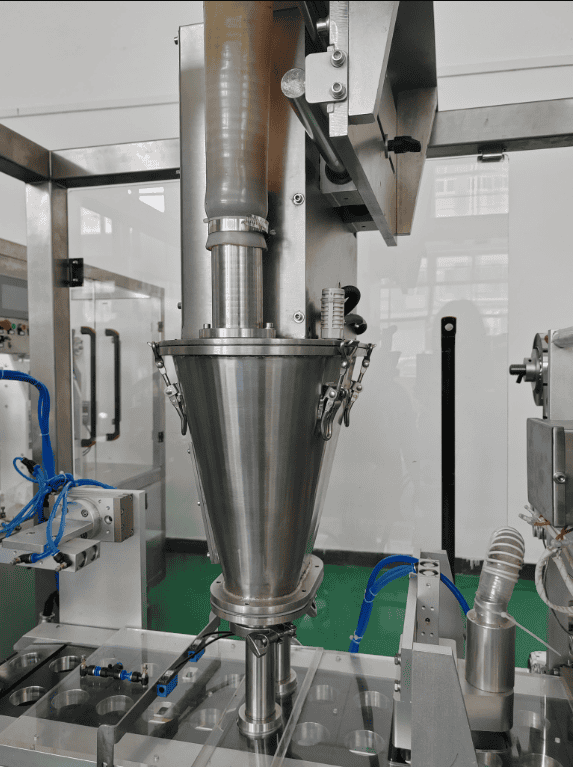

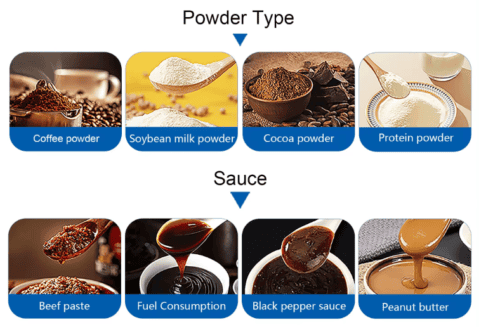

l Servo motor filling high precision high-speed positioning movements, filling error less than 0.1 grams.

l Protection acrylic dust cover.

l No capsule not filling, no lid not sealing, air cylinder retraction detection.

l Air pressure detection, voltage phase protection, air tank buffer to keep production stable.

l Hopper very easy to be took off and cleaned.

l With wheels to conveniently move.

Adopted with nitrogen flushing 3 times.

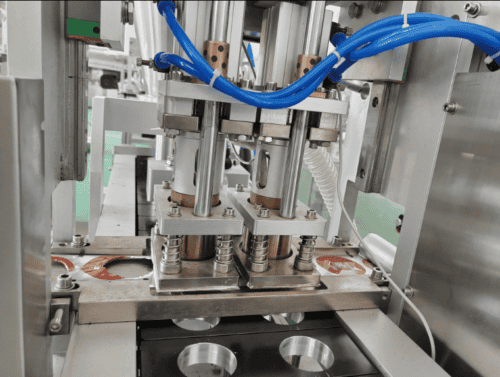

Machine details:

| Work Process | # Capsules loading | Capsules stack together, loading one by one, pneumatic type, nespresso shape capsule type. |

| # Nitrogen flushing 1st | Flush nitrogen into empty nespresso capsule. | |

| # Nitrogen flushing 2nd | Flush nitrogen into hopper, coffee in a nitrogen environment. | |

| # Coffee filling & pressing | Accuracy error +/- 0.1 grams, vertical screw filling type, volume can be adjusted, all parts contact with coffee are made of SUS-304. | |

| # Nitrogen flushing 3rd | Flush nitrogen before foil lid placing. | |

| # Foil lid loading | Pick and place foil lid on filled capsules. | |

| # Sealing | Copper sealing heads, temperature can be adjusted, pneumatic sealing type. | |

| # Finished cups drop | Finished cups automatic drop down, can be built to other type. | |

| # Mold cleaning | Checking mold plate empty and then cleaning. |