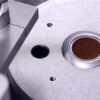

Fully Automatic Rotary Coffee Capsules Filling Sealing Machine

1.SR-1 fully automatic filling sealing machine is specially designed for big scale coffee capsule production,which can automatically complete dropping cup, powder filling, mechanical hand suck lids,Chamber close, Nitrogen flushing, sealing, capsules out from machine.

2. This system equips with world famous electrical elements. Like colorful Weinview touch screen. Temprature controller. Mitsubishi PLC.

3. All the parts of machine which contact with powder are made of 304# stainless steel.

4. Capacity 1100–1300pcs/h , machine can be customized per your request.

Provide flexible one-stop solutions for big scale productions, different coffee flavor testing, shelf life testing, new items promotion and market research etc. strong after-service supports. Economic coffee pod filling sealing machine .

Datos técnicos principales:

| Cabezal de llenado | 1 |

| Capacidad | 1100–1300 cups/H |

| Medir el camino | Auger/Screw filling |

| Gama de llenado | 5-15g (adjustable) |

| Potencia | 1.2KW |

| Voltage | 220V 50-60Hz |

| Material de sellado | Tapa de lámina troquelada |

| Equipamiento opcional | Compresor de aire |

| Air consumption | 0.3 m/min |

| Nitrogen consumption | 0.25m/H |

| Dimensiones generales | 120*120*185cm |

| Peso | 420KG |

| Manera de embalar | Caja de madera |

Machine Working Every Step:

| Dropping cups | Cups drop down one by one automatically |

| Tank mixing | Mixingcoffee powder |

| Filling model | Sinfín de llenado |

| Press coffee | Tamp coffee tightly when filling |

| Sucking die-cut lids | Put lids on cups |

| Heat sealing | 30-3000C , adjustable |

| Cups out from machine | Push-out finished cups to a platform |

Functions:

>Automatic dropping cups

>Automatic screw filling and tamp coffee powder

>With function of Nitrogen Flushing system

>Automatic suck and put pre-cut lids

>Automatic sealing

>cups out from machine automatically

>Touch Screen with English and Chinese

>Machine frame #304 Stainless steel with thickness of 2mm

Payment method: 50% deposit, and 50% by T/T before delivery goods.

Fecha de entrega: 50-60 days after receiving the deposit and cup samples.

Machine Structures:

A: Control system: Mitsubishi PLC Controller+ 7inch True color touch screen. pneumatic+ electrical drive, to make sure machine work stable.

B: PANASONNIC servo motor

C: Japan Omron relay, keep machine work with less than ±2℃ accuracy.

D: Cylinder: Air TAC cylinder.

E: Molds : Used acid-proof molds.

F: The filling system and parts which touch with coffee are all made of 304 stainless steel.

G: Filling system: Screw feed and tamp coffee powder . With mix tool (Auger) in the hopper, ensure the coffee to fall from the hopper , avoid coffee powder got stuck when filling.

Vídeo de trabajo:

Quiénes somos

SANEU, is coffee capsule packaging equipment manufacturer, we focus on coffee capsule packaging (K cup, Nespresso, Lavazza, Dolce Gusto etc) and concentrate every corner of machine. Our machine from design, raw material picking up, process (mechanical processing+artificial buffing), assemble to testing are finished under a set of rigid procedure.

We can design different models to meet the need of different shapes containers.